(1) Please set the pressure of oil pressure switch on 1kg.

(2) If the pressure is too high on Section 1 or Section 2 pressure level, please check matters below :

ˇ Check damages of Section 1 on exhause valve.

ˇ Check damages of Section 2 on Intake valve.

ˇ Check broken of Inlet valve spring

(3) Outside pipeline have to be clean when temperature of cooler (section 1, section2, seciton3) over 55℃.

(4) The function of valve is discharge air of internal air of section 1 and 2 in the spatial vehicle hour. The work of motor won’t be overload while machine with full-loading.

(5) The function of Electronic Automatic Water Drain is discharge air condensing water of section 1 and 2. Air condensing water will infiltrate into crankshaft. Please clean the Water Drain on every 240 hours usage. .If Electronic Automatic Water Drain cannot normally work,please alter to manual action. Please discharge water on every two hours usage.

(6) The use of 35kg relief valve adjusts to 5~ the ~ 6kg unloader. The unloader is not easy to damage on this adjustment.

(7) It’s the best for that the loading of motor does not over 10% of normal electric current

(8) The lubricating oil generally uses for 5,000 hours to have to replace a time. If the machine work in action on long time hour or on 24 hours not stop working continually, please change the lubricating oil for every 4,000 hours accessing time.

(9) Air strainer has to be clean every one month and have to be replaced every 6 months. If the humidity is higher or dust is heavy on the working environment, please consider to change the Air strainer more often.

(10) INTAKE/EXHAUSE VALVE Replacement schedule

1.1. Specialties of the Fu Jih Air Compressors

- Nice appearance, novel design, and excellent durability.

- Nice compressing and mechanical efficiency, having the best effects with the minor motive power.

- Excellent structures with minor noise and vibration.

- All the machine parts are managed by strict quality control, having high precision and alternative. It’s easy to maintain.

2.Things to be noted when receiving the goods:

- When you receive the air compressor, please check if it meets the model and specifications that you order.

- Whether all the accessories are complete without nothing missing.

- Whether the parts or components are damaged, and/or the screws loosen and fall off during the transit. In this case, please contact us as soon as possible. We’ll provide you the most satisfactory solution.

3.How to choose the install location

- he operation life of the air compressor depends on where to select the location and how to maintain it. Proper sites and maintenance can extend the operation life of the air compressor, and save any possible sequent expenses in the future. Therefore, please select the sites to install the air compressors as the following tips.

- Choose the places where is well ventilated, dry, clean, and less dusted.

- Places with enough light, so as to check the machine parts, fill the oil, take apart and/or assemble easily.

- Place the machines as horizontally as possible. The side with belts should face the wall with adequate distances, to have easy access to take apart the air compressors and belts.

4.Things to be noted before operating

- Whether all the screws, nuts, and components loosen and fall off.

- Whether the elasticity of the belt is proper. It’s not suitable to be too tight or loose.

- Check if the lubricants in the crankcase are adequate.

- Whether the water used for cooling is enough and smooth.

- Whether the suction tubes are clean.

- Check if every tube and switch is correct.

5.Correct Maintenance

- Frequently keep the machine clean. It’s better to clean it every day.

- Open the sluice valve of the air tank, cooling radiator, and cyclone separator twice a day to remove the oil-water. Do it every four hours in the places with more humidity.

- Check the surface of the lubricant once a day, to make sure the lubricating function of the compressor works well.

- Wash the air filter every 15 days. Clean the iron net with the petrol and then dry it. Wash the paper net with the detergent powder or replace with a new one.

- After the lubricant works for the first one hundred hours, please replace with new one. After that, replace the lubricant every one thousand hours. (In the places with more moisture and dust, the lubricant should be replaced every five hundred hours.)

- Take the temperature of the water at least twice every day, and record it (for one hour while the normal operation).

- Wash and investigate the valve set for inhaling and exhausting every half a year appropriately.

6.Lubricating of the air compressor

- The lubricant used for our air compressors is SEA, super heavy oil for car engines from Petro China Company Limited. Use 30# to 40# for summer, while 20#~30# for winter.

- The oil amount for the air compressor should meet the level that the oil surface reaches the upper of the oil meter center.

- Lubricant with high viscosity or other impure oil and waste oil is prohibit.

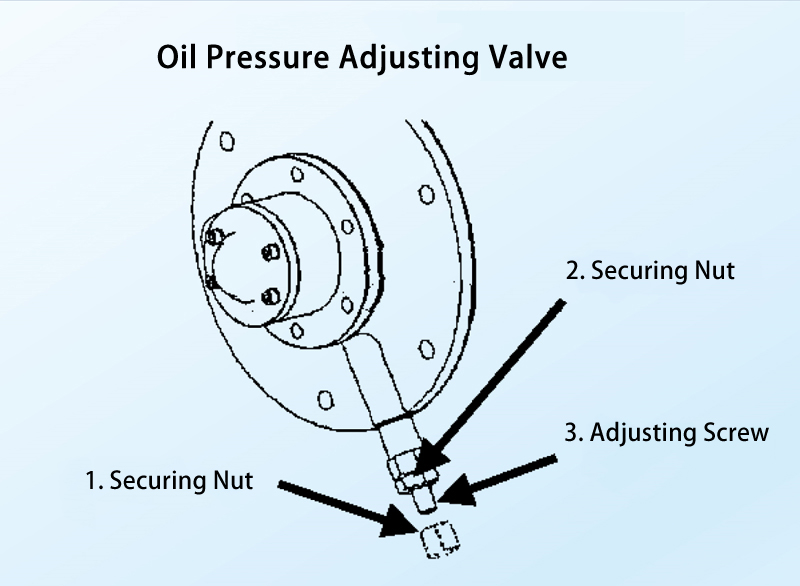

7.Oil Press Adjustment

- Please stay the oil pressure between 1.5 to 3.5 KG/CM2 while normally operating. The methods to adjust are as the following.

- Loosen the firm nuts as shown in the right illustration.

- Rotate to adjust the screw 20927, increasing the pressure if you rotate to the right and decreasing the pressure if you rotate to the left.

- Screw the nut tightly when the pressure reaches the set point to fix the nut 20928 up.

8.Maintenance of the lubricating system

- Check the oil surface once every day. Replace with new oil once after the new compressor operates for one hundred hours. After that, replace the new oil every one thousand hours. Meantime, clean every corner in the sucking oil filter and the crank case, in case of any precipitation.

9.Oil pressure adjustment

- Support with piston hydraulic ingot rings and oil rings.

- Several separate compressing rings are equipped in the grooves of the upper of the outside of the piston. The elasticity of the compressing rings expand evenly in the wall of the cylinder.

- If oil remains in the grooves of the lower of the compressing rings in the outside of the piston, remove the oil in the inside wall of the cylinder.

- The outside diameter of the piston should be smaller than the outside diameter of the piston ring. In this case, when the piston ring wears down, the piston won’t abrade the cylinder directly.

- To maintain the operation life of the piston ring, please note the following.

- Foreign objects and moisture are not allowed to be sucked in.

- Be aware of the cooling status. Do not let the inside wall of the cylinder produce any condensate.